from: http://www.upcraft.it/archives/562

Textiles: Print Your Own Fabrics

If you own a printer that uses pigment inks (rather than the cheaper dye based inks) you can follow these instructions and print your own fabrics.

Beware: Some printers do not like printing on fabric, and using this technique could damage your printer.

Now that the warning is out of the way here is how you can print your own fabric:

Choose a light coloured fabric, and cut it to the maximum width that your printer can handle. I have an Epson R1800, so I can take just over A3+ width of fabric. If your printer supports printing from a roll, then you can make the fabric as long as you like.

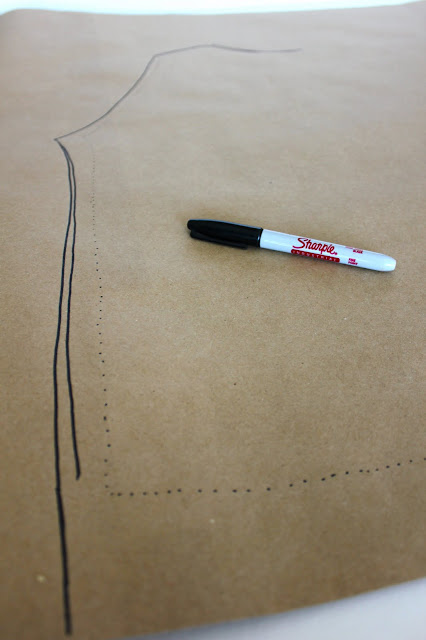

Attach the fabric to a piece of backing paper using double sided sticky tape. The backing paper should be the same width as the fabric, and about the same thickness as copy paper. If you are using a roll feed printer, you could get away with using thin wallpaper or backing paper.You should place the sticky tape at both ends of the fabric, and at several places along the length of the paper.

The purpose of the tape is to stop the fabric from wrinkling up inside the printer, so make sure that the paper and fabric lay flat together without any creases.

Feed the paper into the printer as though it were thick card. On the Epson R1800 I use the roll feed to accept the paper, because the paper enters the printer at a shallower angle.

Create your design on the computer, and print it out. Keep a constant eye on the printer, and watch that the fabric doesn’t get creased or jam up the head. You might want to fiddle around with the brightness / colour settings on your printer to get the design looking right. Each fabric is slightly different, so experimentation is going to be necessary.

Let the design dry for a few minutes, and then pull the fabric off the backing paper. The design should be safe to machine wash, but make sure it’s a cool wash. Hand washing might be preferable if it’s the first time you’ve tried this technique, because not all inks are the same.

When the material is dry, iron at low temperature on the reverse side, with a piece of scrap cloth underneath – just in case the colours transfer by heat.

Beware: Some printers do not like printing on fabric, and using this technique could damage your printer.

Now that the warning is out of the way here is how you can print your own fabric:

Choose a light coloured fabric, and cut it to the maximum width that your printer can handle. I have an Epson R1800, so I can take just over A3+ width of fabric. If your printer supports printing from a roll, then you can make the fabric as long as you like.

Attach the fabric to a piece of backing paper using double sided sticky tape. The backing paper should be the same width as the fabric, and about the same thickness as copy paper. If you are using a roll feed printer, you could get away with using thin wallpaper or backing paper.You should place the sticky tape at both ends of the fabric, and at several places along the length of the paper.

The purpose of the tape is to stop the fabric from wrinkling up inside the printer, so make sure that the paper and fabric lay flat together without any creases.

Feed the paper into the printer as though it were thick card. On the Epson R1800 I use the roll feed to accept the paper, because the paper enters the printer at a shallower angle.

Create your design on the computer, and print it out. Keep a constant eye on the printer, and watch that the fabric doesn’t get creased or jam up the head. You might want to fiddle around with the brightness / colour settings on your printer to get the design looking right. Each fabric is slightly different, so experimentation is going to be necessary.

Let the design dry for a few minutes, and then pull the fabric off the backing paper. The design should be safe to machine wash, but make sure it’s a cool wash. Hand washing might be preferable if it’s the first time you’ve tried this technique, because not all inks are the same.

When the material is dry, iron at low temperature on the reverse side, with a piece of scrap cloth underneath – just in case the colours transfer by heat.